Category:

Classified by product function

Connectors: bolts, flanges, couplings, etc., high-strength, fatigue resistant

Transmission components: gears, worms, lead screws, etc., with high wear resistance and precision matching

Structural components: such as frames, shells, and bases have rigidity and shock absorption properties

Precision components: optical mirror holder, sensor housing, etc., micrometer level tolerance, non-magnetic

Technology:

1、 Traditional cutting techniques

Turning, rotary machining; Milling, multi-faceted machining; Drilling and hole processing; Grinding, high-precision, ultra smooth surface.

2、 Numerical Control Machining (CNC)

3-axis CNC; 4-axis CNC; 5-axis CNC; 6-axis CNC

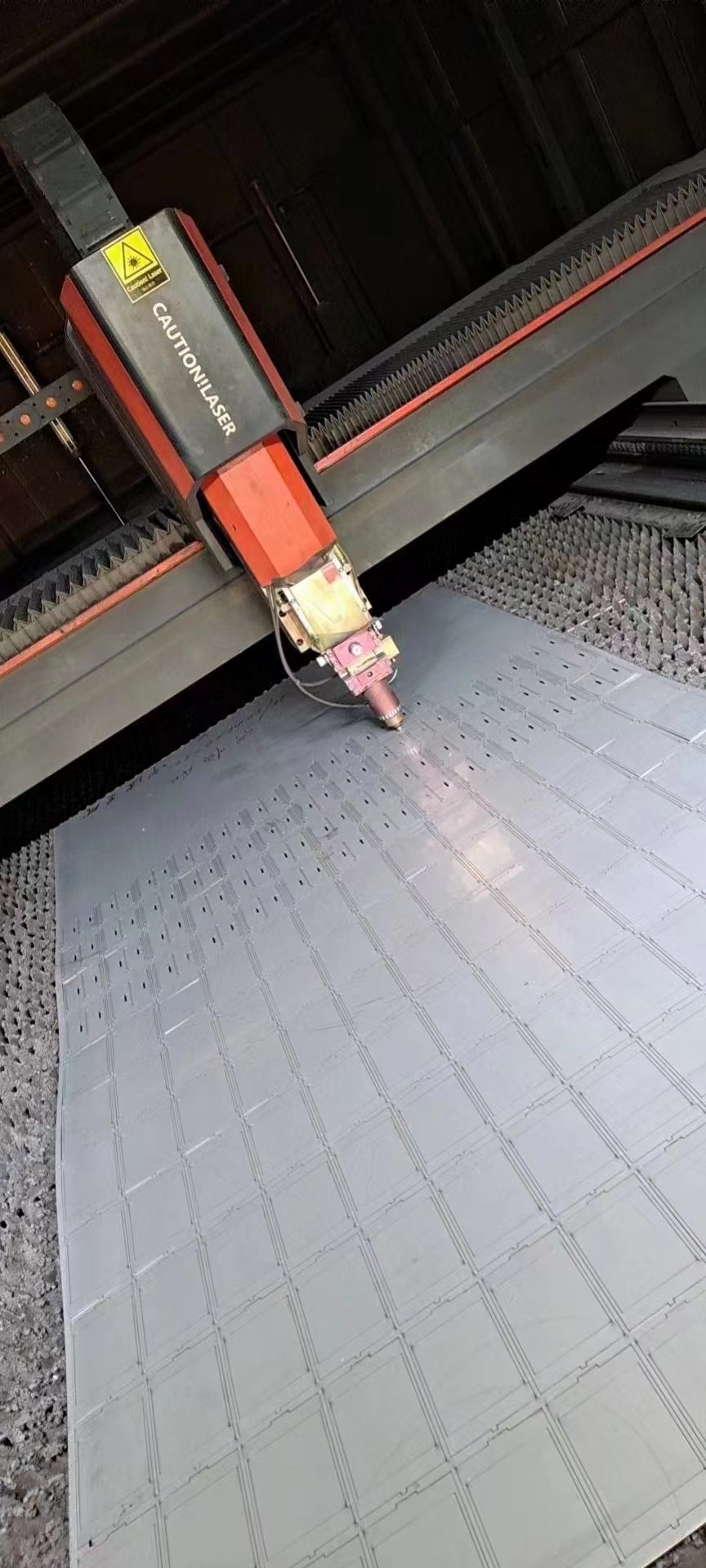

3、 Special processing technology

Electric discharge machining (EDM), electro etching discharge machining; Laser cutting, high-energy beam melting cutting; Water jet cutting, high-pressure water mixed abrasive cutting; Ultrasonic processing, high-frequency vibration abrasive impact.

4、 Surface treatment process

Anodizing; Electroplating rust prevention; Sandblasting; Deburring and matte finish; PVD coating.

5、 Composite process and emerging technologies

Additive+subtractive composite processing; 3D printed blanks followed by CNC precision machining; Ultra precision machining; Nano turning (accuracy ≤ 0.1 μ m, used for optical lenses); Green processing technology; Micro lubrication (MQL) processing.

Material:

1、 Metal materials

Steel products:

45 # steel, high cost performance, easy to cut and rust, requires surface treatment; 40Cr and 42CrMo require preheating treatment for high strength after quenching and tempering; GCr15 high wear-resistant bearing steel; 304/316 stainless steel, corrosion-resistant.

Non ferrous metals:

6061 aluminum alloy, tensile strength ≥ 310MPa; H62 brass, excellent machinability; TC4 titanium alloy, with high specific strength.

2、 Non metallic materials

POM (Saigang) self-lubricating high rigidity; PTFE is resistant to chemical corrosion; Nylon 66 is wear-resistant; PEEK is resistant to high temperatures.

3、 Composite materials

Carbon fiber reinforcement, easy to peel off between layers; Metal based composite materials with high thermal conductivity and low expansion; Ceramic particle reinforced aluminum, high hardness, lightweight.

Application areas:

1、 Industrial manufacturing field

Automotive manufacturing, engineering machinery, and mold industry

2、 High end equipment field

Aerospace, semiconductor equipment, optical instruments

3、 Medical and consumer fields

Medical devices, consumer electronics, food machinery

4、 Energy and Heavy Industries

Petrochemical, wind power, nuclear power equipment

5、 Emerging field applications

New energy vehicles (battery casing, motor shaft), robot joints, 3D printing post-processing

Production & Processing

Laser Cutting forging Stainless Steel 316/316L/304/304L Forged Gear/Gear Wedge

Keyword:

Laser Cutting/Welding/Bending

Forging

Get a Free Quote

If you need more information about our products, please feel free to contact us, we will provide you with professional service personnel, we will reply promptly after receiving the information.

Related Products

FAQ

Q

Can we have a tour of the factory?

A

We are more than happy to welcome visitors to our company to see our machining shop.

Q

How long do the products take?

A

The time from order confirmation to shipment will vary according to the inventory of the required products, processing and production, etc. The exact time can be confirmed by communication.

Q

In which port is the transportation?

A

Zhoushan Port, Ningbo.

Q

What methods of payment do we support?

A

T/T,