Category | Classified by product structure | Shaft parts: mainly used to support rotating components and transmit torque, such as motor shafts, machine tool spindles, etc. |

Disk type parts: usually have large rotating surfaces, such as gears, flanges, etc. | ||

Box type parts: used to accommodate and support other components, with complex internal cavity structures, such as gearbox boxes, engine cylinder blocks, etc. | ||

Bracket components: They play a supporting and connecting role, with various shapes, such as the columns of machine tools and the brackets of robotic arms. | ||

Technology | Cutting process technology

| 1. Milling: Using milling cutters to machine workpieces in a CNC milling machine or machining center for flat, contour, cavity, and other machining. 2. Turning: On a CNC lathe, rotating parts are machined by relative motion between a rotating workpiece and a fixed tool. 3. Drilling: Use a drill bit to create various holes on the workpiece. 4. Boring: Used for machining high-precision holes, especially for large diameter holes and hole systems with positional accuracy requirements. |

Grinding processing technology

| 1. Flat grinding: Grinding the flat surface of the workpiece with a grinding wheel to obtain high flatness and surface smoothness. 2. External cylindrical grinding: mainly used for machining rotating surfaces such as cylindrical surfaces and conical surfaces. 3. Internal circle grinding: used to grind the surface of the inner hole of the workpiece, and can process various shapes of inner holes. | |

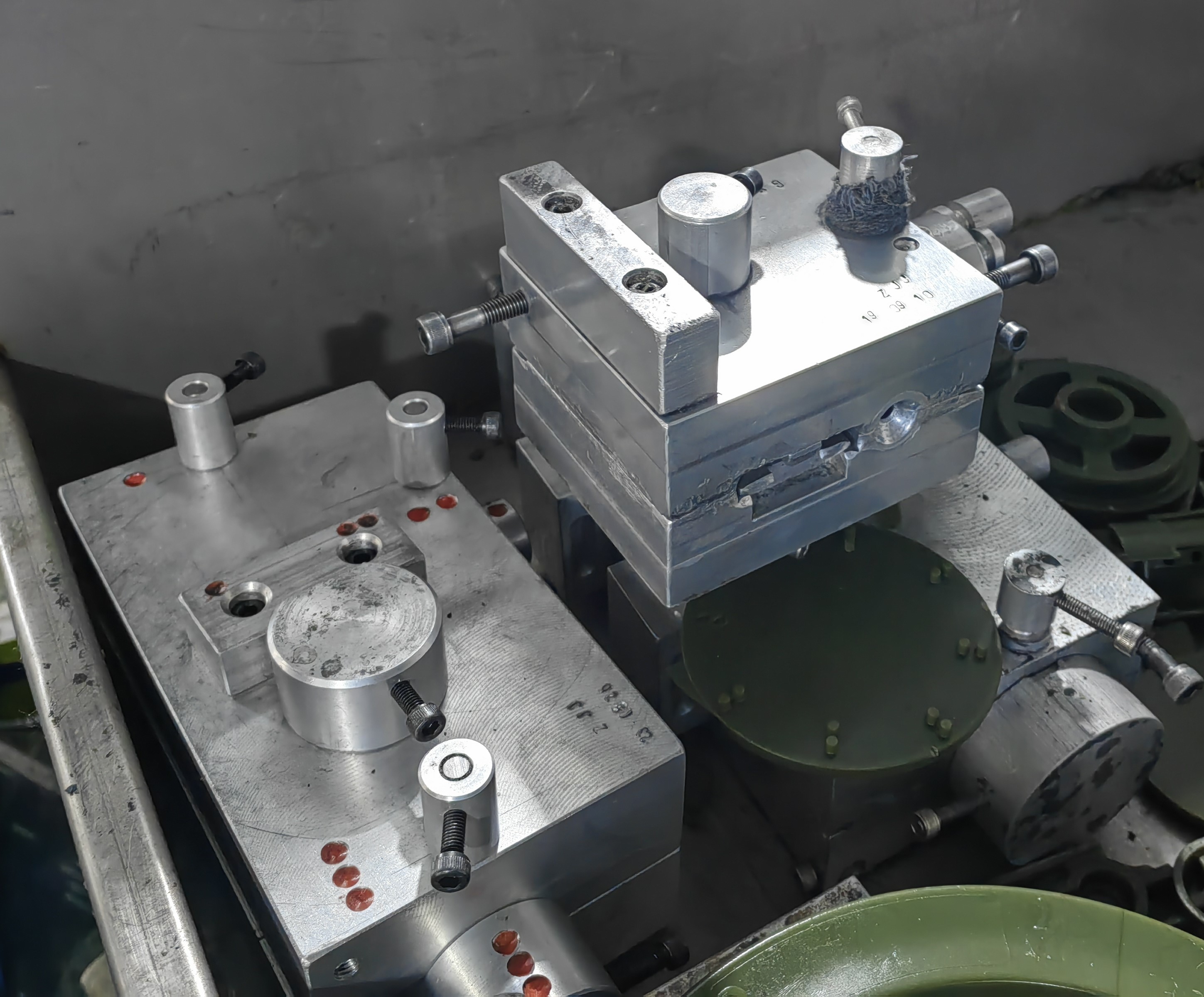

Special processing technology

| 1. Electric discharge machining: Using the high temperature generated by pulse discharge to corrode metal materials and process complex shaped parts. 2. Wire cutting processing: By using electrode wire discharge to cut workpieces, various shapes of two-dimensional contours can be machined. | |

Other processing techniques

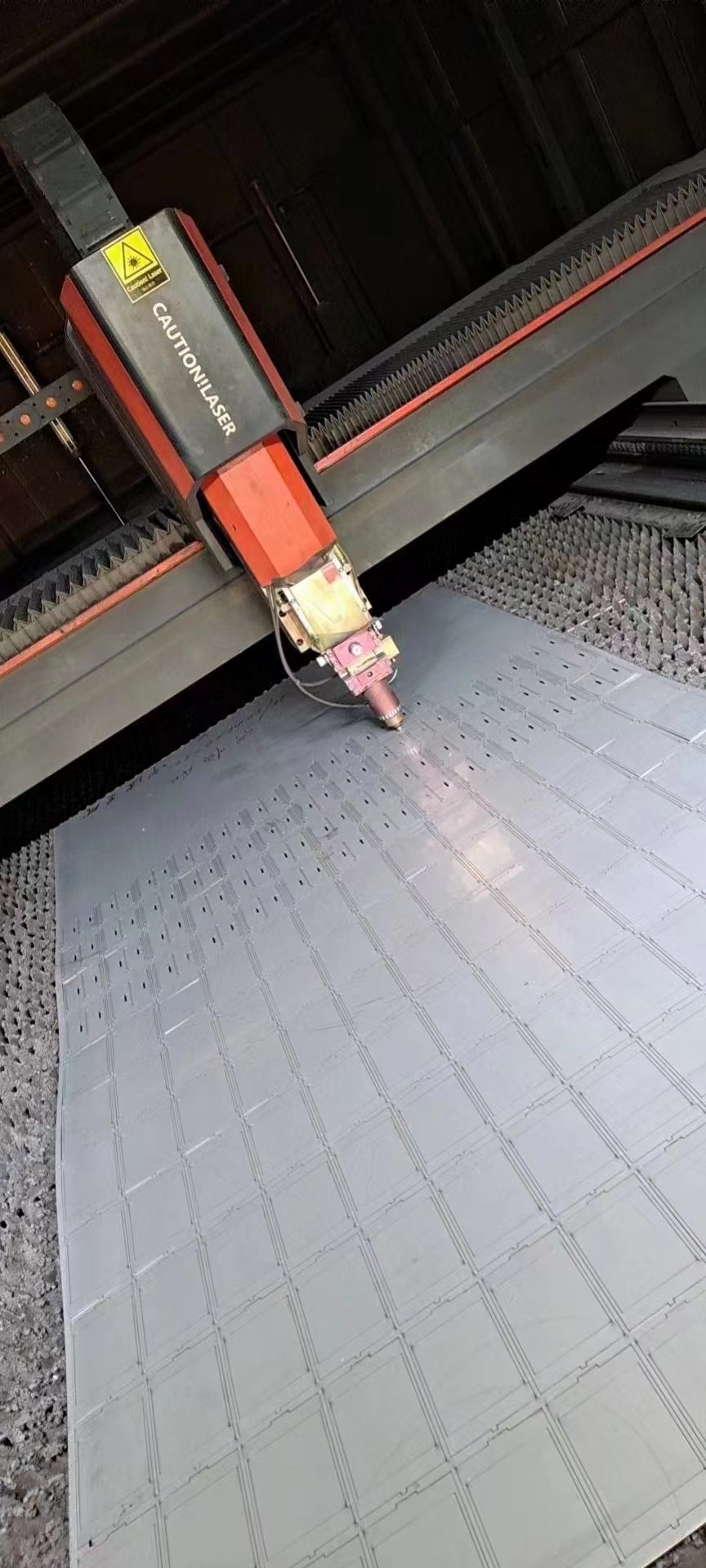

| 1. Laser processing: Using high-energy density laser beams for cutting, welding, drilling, surface treatment, and other processing of materials, it has the advantages of high precision, fast speed, and non-contact. 2. Ultrasonic processing: suitable for processing hard and brittle materials. |

Production & Processing

Stainless Steel 316 High-Pressure Valve for Oil and Gas Pipelines by Advanced Abrasive Water Jet Machining Technology

Keyword:

CNC Machining Parts

Oil Field Equipments and Parts

Get a Free Quote

If you need more information about our products, please feel free to contact us, we will provide you with professional service personnel, we will reply promptly after receiving the information.

Related Products

FAQ

Q

Can we have a tour of the factory?

A

We are more than happy to welcome visitors to our company to see our machining shop.

Q

How long do the products take?

A

The time from order confirmation to shipment will vary according to the inventory of the required products, processing and production, etc. The exact time can be confirmed by communication.

Q

In which port is the transportation?

A

Zhoushan Port, Ningbo.

Q

What methods of payment do we support?

A

T/T,