Advantages of silica sol casting process:

1. The product shape is more complex. We can produce thin-walled, deep cavity, fine pore, and textured products. Can directly form parts that are close to the final shape.

2. More precise dimensional tolerances. Usually able to achieve tolerance control of ± 0.005 inches/inch (± 0.127mm/25.4mm) or better.

3. Better surface smoothness. The surface roughness of castings can usually reach Ra 1.6-3.2 μ m (63-125 μ in), or even better, reducing machining workload, lowering costs, and shortening cycles.

4. Widely applicable materials. High alloy steel, stainless steel, and titanium steel are all suitable.

5. Excellent performance.

Application areas of silica sol casting products:

1. Aerospace: turbine engine blades, guides, casings, fuel injectors, brackets, complex structural components.

2. Medical devices: precision instrument components

3. Energy and Industry: Gas turbine components, valves, pump casing impellers, heat exchanger components, shells.

4. Automobile: turbocharger impeller, exhaust manifold, engine parts, precision components.

5. Food and chemical industry: corrosion-resistant pump valves, stirring blades, valves.

6. Military industry: missile components, radar structural components, precision parts.

7. Others: golf club heads, hardware, art pieces, watch parts.

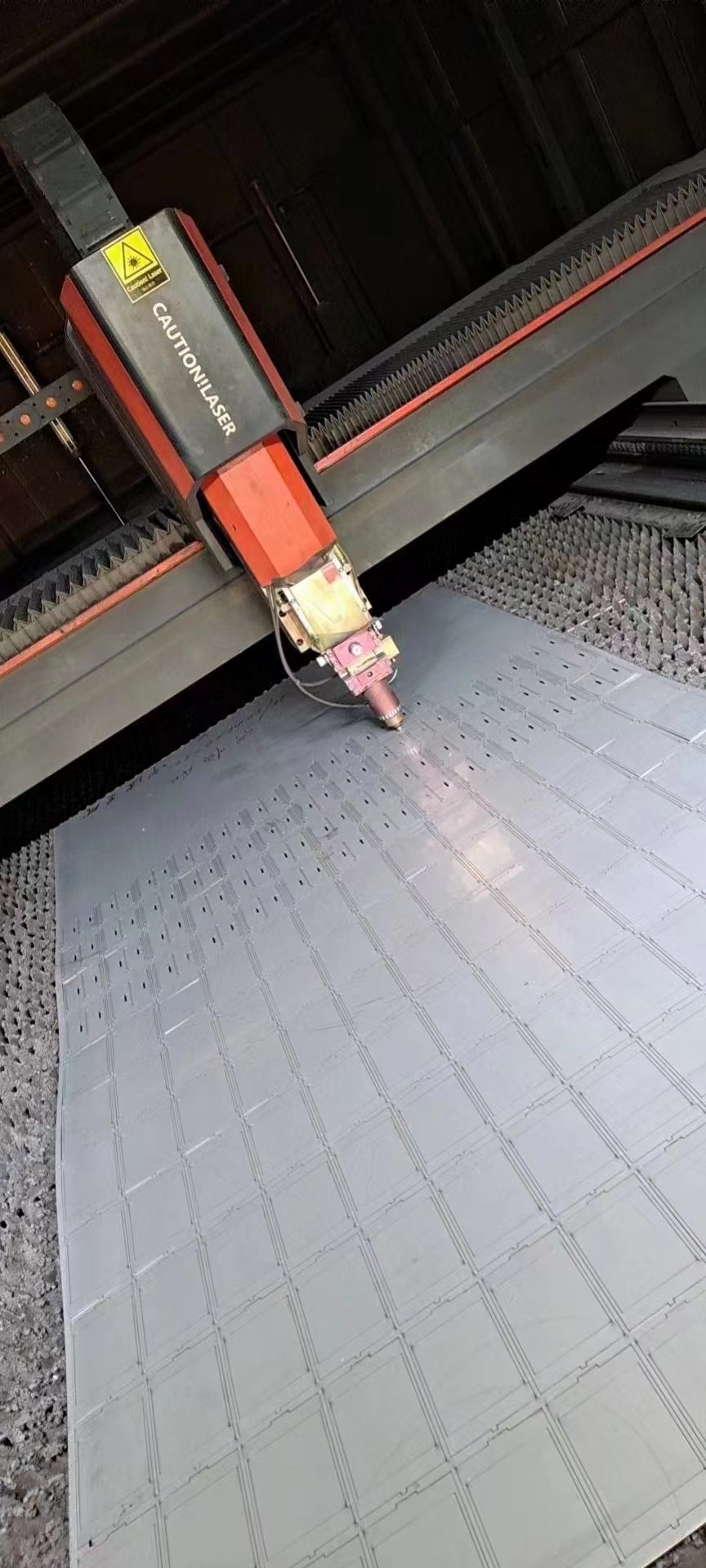

Here is our workshop display:

Here are some of our company's product displays:

Production & Processing

Silica sol precision casting material cast steel

Keyword:

Casting

Get a Free Quote

If you need more information about our products, please feel free to contact us, we will provide you with professional service personnel, we will reply promptly after receiving the information.

FAQ

Q

Can we have a tour of the factory?

A

We are more than happy to welcome visitors to our company to see our machining shop.

Q

How long do the products take?

A

The time from order confirmation to shipment will vary according to the inventory of the required products, processing and production, etc. The exact time can be confirmed by communication.

Q

In which port is the transportation?

A

Zhoushan Port, Ningbo.

Q

What methods of payment do we support?

A

T/T,