Sand Casting

Advantages:

1. Size flexibility: from small items weighing a few grams to large items weighing hundreds of tons.

2. Material adaptability: Sand casting can be applied to various materials.

3. Structural inclusiveness: capable of forming structures with complex internal cavities, deep holes, curved surfaces, etc. that are difficult to achieve through mechanical processing.

4. Economy:

Low mold cost: Compared to metal molds, wooden, plastic, or metal molds have significantly reduced costs and are suitable for small batches, large parts, or trial production.

The raw material cost is low and recyclable.

5. Response and design changes: The mold manufacturing cycle is relatively short, and design modifications are relatively easy, especially suitable for product development stages or customized needs.

Material :

1. Molding sand: natural silica sand, zirconium sand, chromite sand, etc.

2. Adhesive: clay, water glass, various resins.

3. Additives: Coal powder anti sticking sand, wood chips to increase air permeability.

technological process:

1. Mold making: Make models and core boxes according to the part drawings.

2. Molding: Compact the molding sand mixture around the model to form the outer contour of the mold.

3. Core making: Create a sand core in the core box to form the inner cavity of the component.

4. Molding: Accurately place the sand core into the lower sand mold, close the upper sand mold, and form a complete mold cavity.

5. Pouring: Smooth and continuous injection of molten metal into the mold cavity.

6. Cooling and solidification: The molten metal is cooled and solidified in the mold cavity to form a shape.

7. Sand removal: Crush the sand mold, remove the casting, and remove sprues, burrs, and sand sticking.

8. Post treatment: heat treatment, surface cleaning, machining, inspection, etc.

Application areas:

1. Automotive industry: engine cylinder block, cylinder head, gearbox housing, chassis components, brake discs, flywheel.

2. Construction machinery: counterweights, track shoes, hydraulic valve bodies, large gearbox bodies, and structural components for excavators/loaders.

3. Energy and electricity: wind power equipment hub, base, gearbox; Valves and impellers for hydroelectric equipment; Nuclear power equipment pump casing; Heavy duty gas turbine casing.

4. Machine tool equipment: large basic structural components such as bed, column, worktable, spindle box, etc.

5. General machinery: pump casing, valve body, reducer casing, compressor cylinder body.

6. Pipeline valves: valves, fittings, and flanges of various materials and specifications.

7. Rail transit: locomotive bogie components, braking system components.

8. Building hardware: decorative components, structural components, and pipe fittings.

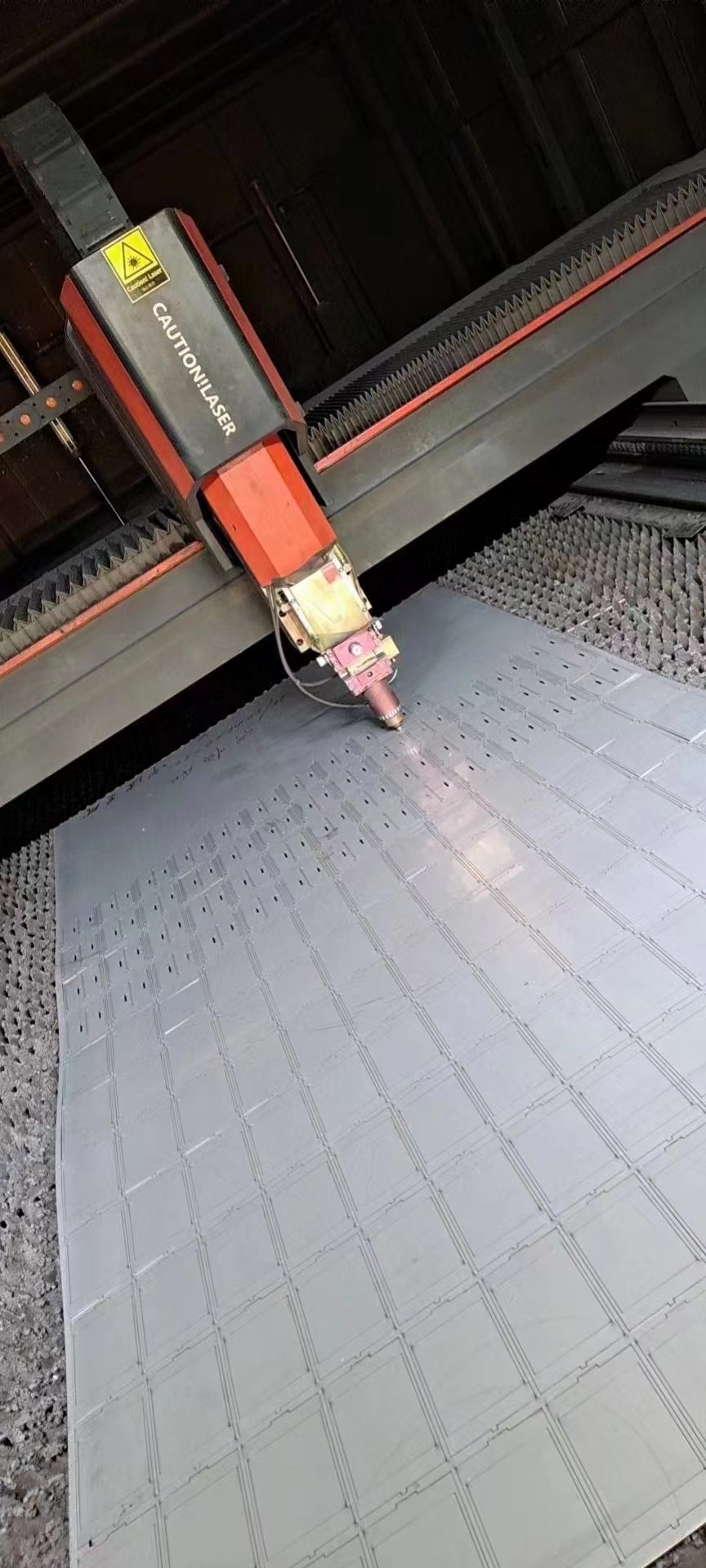

Here are some of our company's product displays:

Production & Processing

Customized Precision Casting Hydralic Engineering Sand Casting

Keyword:

Casting

Get a Free Quote

If you need more information about our products, please feel free to contact us, we will provide you with professional service personnel, we will reply promptly after receiving the information.

Related Products

FAQ

Q

Can we have a tour of the factory?

A

We are more than happy to welcome visitors to our company to see our machining shop.

Q

How long do the products take?

A

The time from order confirmation to shipment will vary according to the inventory of the required products, processing and production, etc. The exact time can be confirmed by communication.

Q

In which port is the transportation?

A

Zhoushan Port, Ningbo.

Q

What methods of payment do we support?

A

T/T,