Water glass casting

Process principle:

1. Sand mixing: Raw sand+water glass → mix evenly.

2. Styling/Core making: Fill the mixed sand into the mold and compact it by hand or machine.

3. Blow hardening: Silica gel precipitates to form a three-dimensional network, strongly bonding sand particles to achieve high strength.

4. Demoulding and shaping: Immediately remove the mold after hardening and repair any damaged areas.

5. Box casting: Assemble sand molds and pour molten metal.

6. Sand removal: Shake the casting to remove sand after cooling.

Advantages:

1. Fast hardening speed and increased efficiency:

CO ₂ blown into shape in seconds, significantly reducing the production cycle.

2. High strength and strong anti-interference ability:

After hardening, it has high strength and is not easily deformed during transportation, reducing the risk of sand flushing and box collapse.

3. Environmentally friendly, green casting pioneer:

-No formaldehyde/phenol toxic gas, better environment than resin sand;

-Old sand is easily regenerated by wet method, with a recovery rate of over 80% and low solid waste emissions.

4. Low cost and outstanding economy:

-The price of water glass is only 1/5-1/3 of that of resin;

-CO ₂ gas is cheap and easy to obtain, with low energy consumption.

5. Wide material adaptability:

-Especially suitable for high-temperature materials that are sensitive to nitrogen and sulfur;

Application areas:

1. Heavy machinery: large machine tool bed, steel rolling frame, mining crusher jaw plate, 10000 ton hydraulic press base

2. Cast steel parts: power station valve body, turbine blades, steel ingot mold, wear-resistant gear plate, slag tank, container corner parts

3. Construction vehicles: excavator counterweights, track shoes, large gearbox bodies

4. Shipbuilding: anchor chain wheels, mooring bollards, thruster brackets

5. Chemical equipment: acid resistant pump casing, reactor lining substrate

6. Rail Transit: Train Hook Tongue, Buffer Shell, Switch Accessories

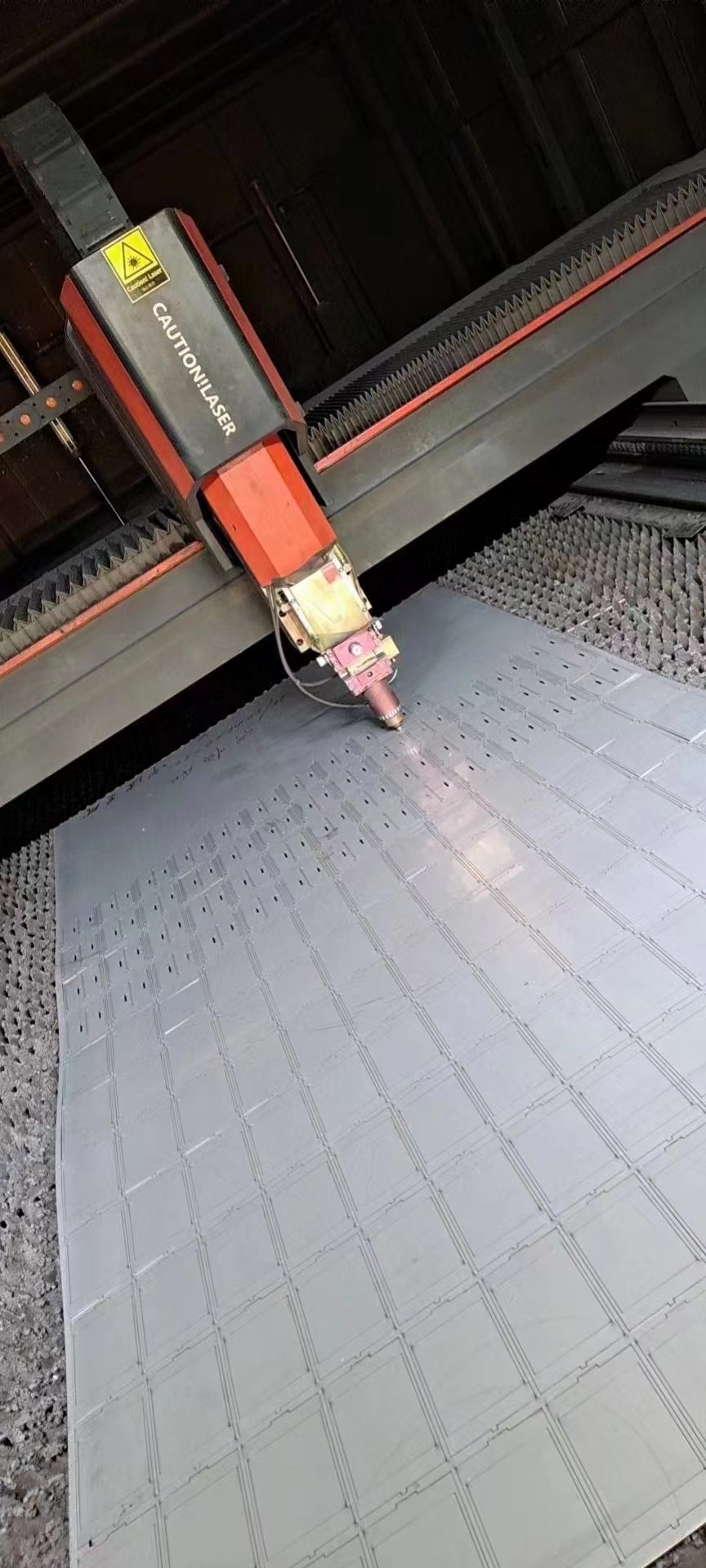

Here are some of our company's product displays:

Production & Processing

Casting Hydro Turbine Parts Water Glass Casting

Keyword:

Casting

Get a Free Quote

If you need more information about our products, please feel free to contact us, we will provide you with professional service personnel, we will reply promptly after receiving the information.

Related Products

FAQ

Q

Can we have a tour of the factory?

A

We are more than happy to welcome visitors to our company to see our machining shop.

Q

How long do the products take?

A

The time from order confirmation to shipment will vary according to the inventory of the required products, processing and production, etc. The exact time can be confirmed by communication.

Q

In which port is the transportation?

A

Zhoushan Port, Ningbo.

Q

What methods of payment do we support?

A

T/T,