7、Shell Casting Details Page

Principles and processes of craftsmanship

1. Preparation of coated sand:

Quartz sand+thermosetting phenolic resin (binder)+Urotropin (curing agent)+Calcium stearate (lubricant) → Mix evenly to make coated sand.

2. Shell making:

Template preheating: Heat the metal template to 230-300 ℃.

Sand covered crust: Template buckle film sand box, flip to make the sand particles adhere to the hot template, and the resin melts.

Curing and shaping: Keep heating, the resin crosslinks and solidifies to form a hard thin shell.

Demoulding and shell removal: The ejector mechanism separates the sand shell from the template.

3. Shell type combination:

Assemble the two halves of the shell into a complete cavity using fixtures or resin adhesives.

4. Pouring and Cooling:

Place the shell into a sand box filled with sand support, pour molten metal, and cool to solidify.

5. Shedding and cleaning:

Crush the sand shell, remove the casting, and clean the burrs.

Advantages:

1. Dimensional accuracy:

The metal template ensures the stability of the cavity size, and the casting tolerance is significantly smaller than that of ordinary sand casting.

2. Surface smoothness:

The combination of fine coated sand and smooth template results in a delicate casting surface, reducing cleaning and machining costs.

3. High production efficiency and automation potential:

Short shell making cycle, suitable for assembly line operation;

Easy to achieve automation in shell making and molding, with an efficiency 5-10 times higher than manual sand molds.

4. Stable and consistent quality of castings:

The shell has high strength, is not easily deformed, and reduces sand flushing and box expansion defects;

Moderate breathability reduces the risk of porosity.

5. Good adaptability between materials and design:

Suitable for materials such as cast iron, cast steel, copper alloy, aluminum alloy, etc;

Can produce complex structures with small sand cores.

6. Cost savings:

The sand consumption is only 1/10 of that of green sand, and the old sand can be recycled and reused;

Reduce machining allowance and lower metal and labor costs.

Application areas:

1. Automotive components: crankshaft, camshaft, connecting rod, gear, rocker arm, small housing, brake drum.

2. Hydraulic and fluid systems: valve body, pump casing, fittings, hydraulic motor casing.

3. Construction machinery: sprockets, bushings, wear-resistant plates, small transmission components.

4. General machinery: gear blanks, flanges, pipe fittings, hardware tools (wrenches, pliers).

5. Agricultural machinery: seeder parts, harvesting blades, transmission box.

Here are some of our company's product displays:

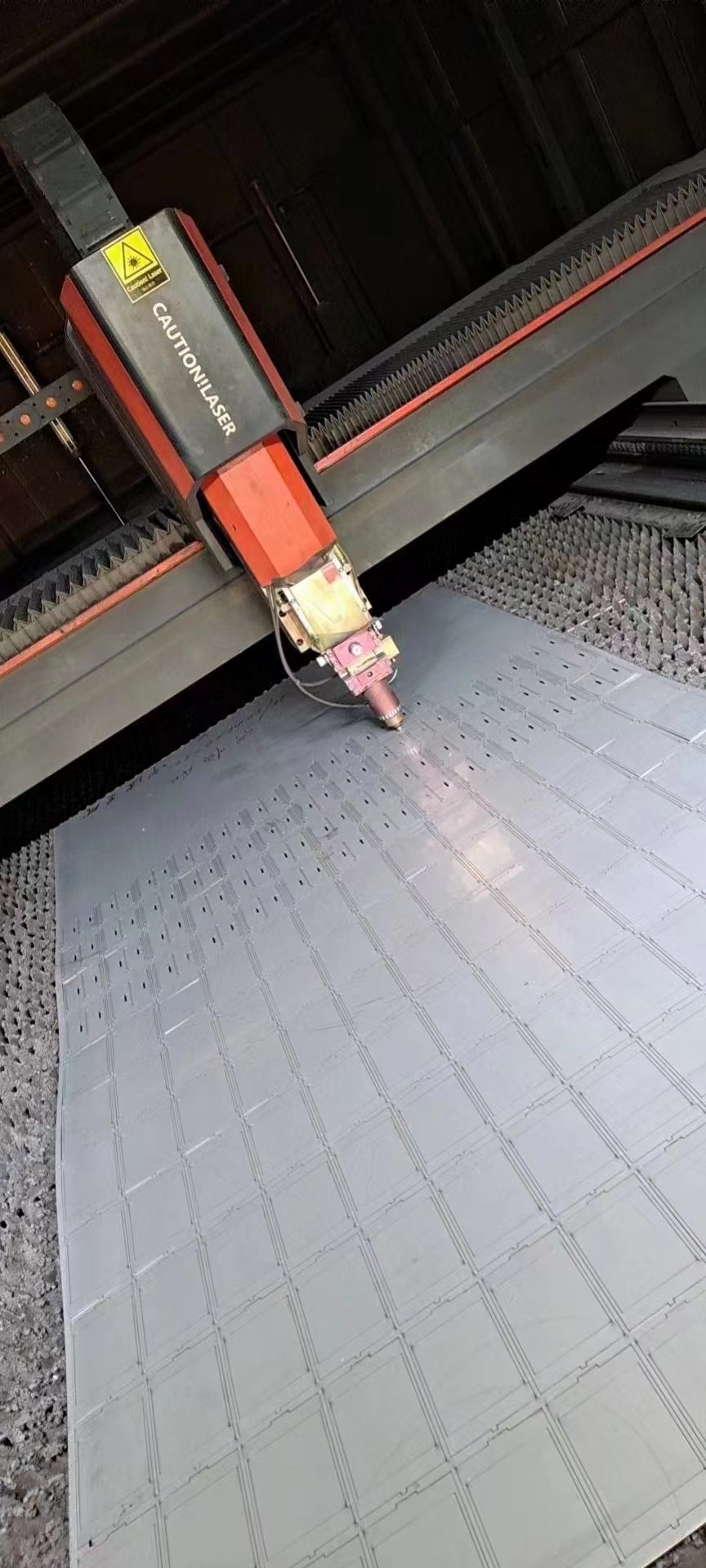

Production & Processing

Zamac Alloy Casting Lighting Accessories Shell Mold Casting

Keyword:

Casting

Get a Free Quote

If you need more information about our products, please feel free to contact us, we will provide you with professional service personnel, we will reply promptly after receiving the information.

Related Products

FAQ

Q

Can we have a tour of the factory?

A

We are more than happy to welcome visitors to our company to see our machining shop.

Q

How long do the products take?

A

The time from order confirmation to shipment will vary according to the inventory of the required products, processing and production, etc. The exact time can be confirmed by communication.

Q

In which port is the transportation?

A

Zhoushan Port, Ningbo.

Q

What methods of payment do we support?

A

T/T,