Details page of die-casting castings

Advantages:

1. More precise dimensions and better surface finish

Precise molds, high-pressure molding - more stable and precise in size, with strict tolerance control.

After molding, the surface of the casting is smooth and delicate, which can be used directly or only requires a small amount of subsequent processing, reducing the cost and time of secondary processing.

2. Mechanical properties and structural strength:

Formed under high pressure, die-casting parts have good strength, hardness, and rigidity, which can produce more complex products while reducing weight and maintaining structural integrity.

3. Large scale production capacity:

The die-casting process has a short cycle time, high production efficiency, and is suitable for mass production.

It can improve productivity and reduce costs.

4. Wide range of materials available: aluminum alloy die-casting parts, zinc alloy die-casting parts, magnesium alloy die-casting parts, copper alloy die-casting parts

Application areas:

1. Automotive industry: engine cylinder/head, gearbox housing, brackets, structural components, steering system parts, new energy vehicle battery pack housing/end plates, motor housing, etc.

2. Electronic appliances: phone/laptop shells, radiator shells, connector shells, motor end caps, LED lamp sockets/shells, power tool shells, etc.

3 Communication equipment: base station filter housing, antenna components, router/switch housing, etc.

4. Household appliances: washing machine/air conditioner/refrigerator parts, vacuum cleaner parts, kitchen appliance casings and structural components, etc.

5. Industrial equipment: pump valve housings, pneumatic/hydraulic components, robotic arm parts, instrument housings, etc.

6. Hardware and consumer goods: door lock handles, bathroom accessories, toy models, sports equipment parts, etc.

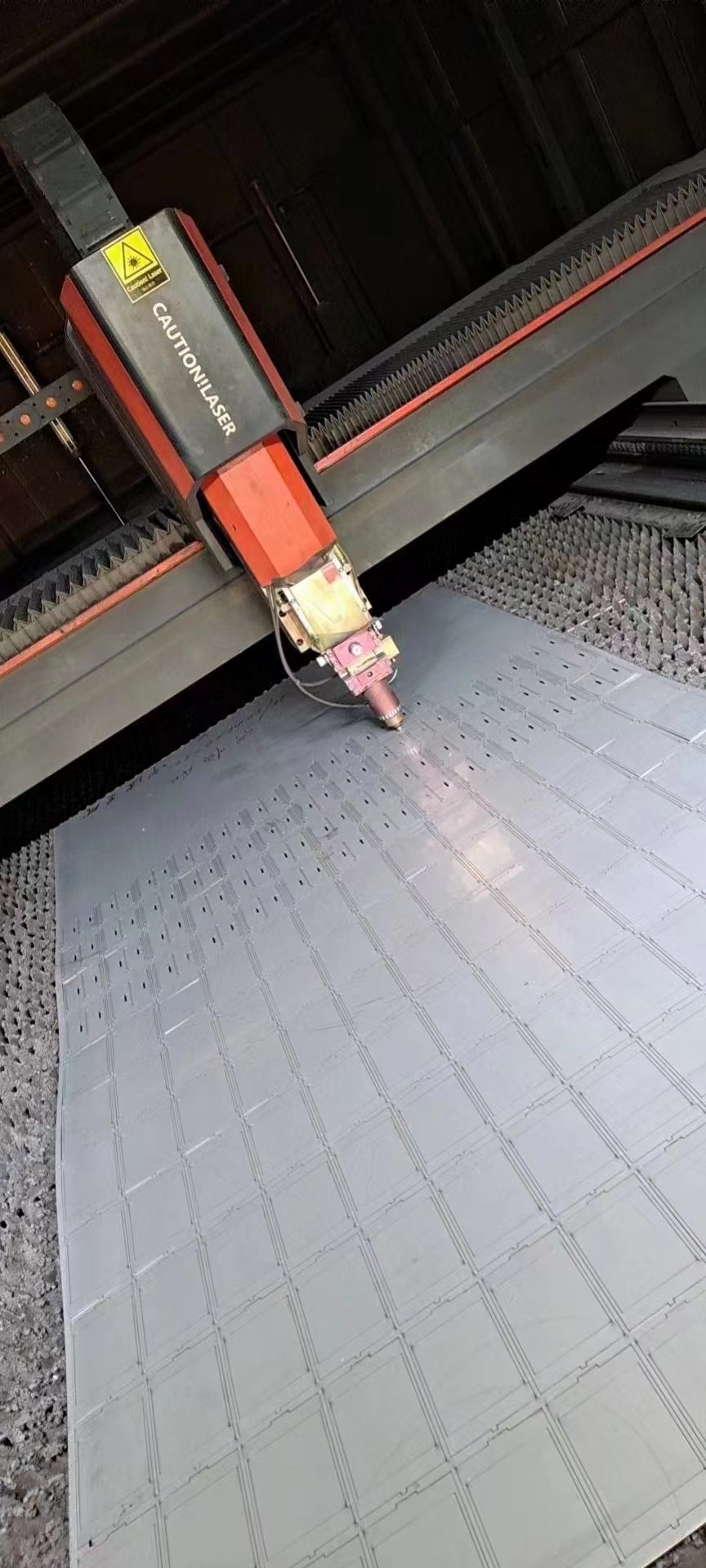

Here are some of our company's product displays:

Production & Processing

High Temperature Alloy Casting Machined Parts

Keyword:

Casting

Get a Free Quote

If you need more information about our products, please feel free to contact us, we will provide you with professional service personnel, we will reply promptly after receiving the information.

Related Products

FAQ

Q

Can we have a tour of the factory?

A

We are more than happy to welcome visitors to our company to see our machining shop.

Q

How long do the products take?

A

The time from order confirmation to shipment will vary according to the inventory of the required products, processing and production, etc. The exact time can be confirmed by communication.

Q

In which port is the transportation?

A

Zhoushan Port, Ningbo.

Q

What methods of payment do we support?

A

T/T,